![]()

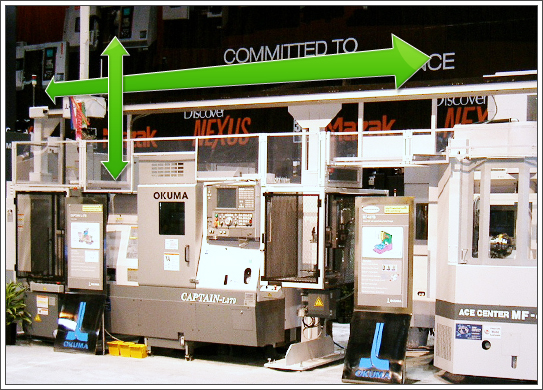

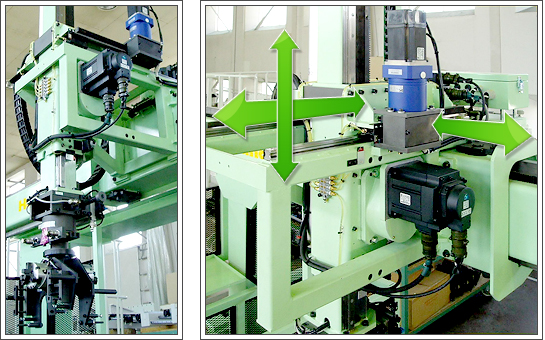

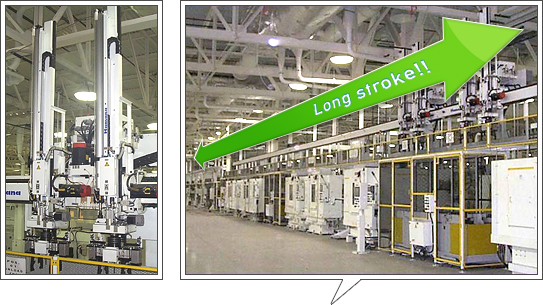

Gantry Loader is Robot-Arm that can transfer workpieces in the factory production line.

It performs quickly and accurately instead of human in transporting, setting, and collecting workpiece.

Not only new machines, the current machines you have also can be retrofitted.

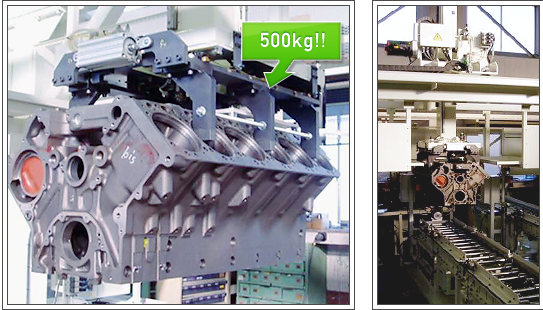

Carry more than 100kgs weight such as cylinder block of engine.

It is proven up to 500kgs.

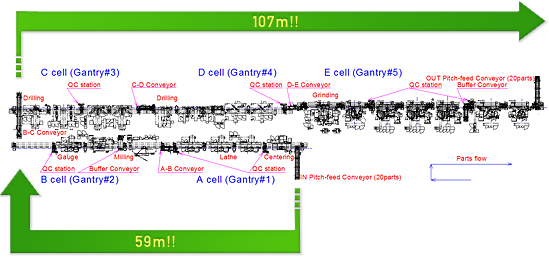

Production line of crank-shaft 150m length.

(Centering Machine 1 unit + Lathe 3units + Milling 2units, Drilling 11units, Grinding 5 units)

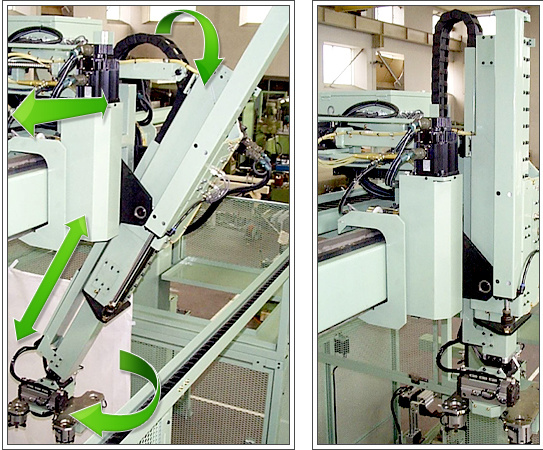

We can achieve one line by Gantry Loader utilizing various technology such as turnning + swing hand.

![]()